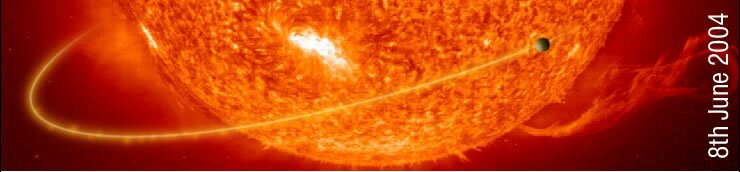

Pictures from the Day

The Transit of Venus seen through the haze from Carr House

We would like to apologise for lack of video from Carr House this morning. This was due to excessive demand on one of our servers. A 12 minute clip can be viewed here. More images...

|

How do I observe the Transit of Venus?

See our safe observing section for four ways to observe the transit. Or look at our "on the web" page for links from around the world.

|

Where can I see the Transit?

Use our Events Calendar to find events in your area. Many observatories, schools, Universities and Science Centres are having Transit events.

|

What can I measure?

See our Transit Calculator for details of the timings you need to make to measure the distance to the Sun. You need to look at this before the day to be sure you have the equipment.

|